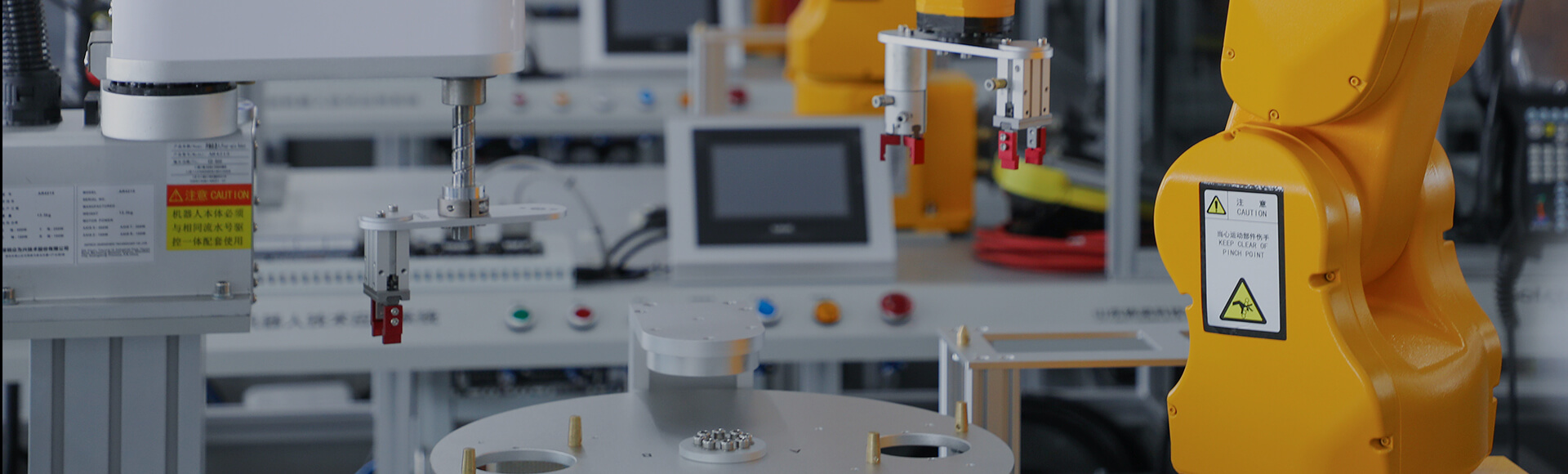

Our manufacturing and engineering departments work in tandem to assist clients in developing innovative and creative products, and then efficiently produce said products to the highest possible standard. We also maintain an in-house industrial engineering team dedicated to developing proprietary technologies to help further automate our manufacturing processes. Our annual output can reach 350 million pieces, covering different soft/hard toys, clay toys, specialty plush toys, electronic toys, etc. All of our products meet the specifications set out by our clients and have passed relevant national and international safety standard tests,including ISO9001, RBA, GSV, IP, SCC, Disney and Walmart. Nearly 40 years of toy manufacturing expertise ensure superior quality.